Introduction

Lubricants, such as oil and grease are used to reduce friction between mechanical elements like bearing and gears. Over time, the efficiency of lubricant degrades due to oxidation, evaporation or wear debris. Periodical quality inspection of lubricant is recommended to schedule preventive maintenance. This strategy enables high performance, minimizing down time and loss of revenue.

The ASTM methods include the use of FTIR in transmission mode to monitor lubricants in machinery. However, this method has some disadvantages including: (1) correct sample volume and (2) difficulty measuring highly viscous samples such as grease.

In order to address these issues, JASCO offers a lubricant evaluation method using FTIR with attenuated total reflectance (ATR); which is a technique for measuring samples in contact with a high refractive index prism. Therefore, this method can offer micro-volume measurement with minimal sample preparation or pretreatment. In addition, the penetration depth of surface measurement depends on two conditions: (1) incident angle of infrared light and (2) refractive indices of prism and sample. ATR provides both qualitative and quantitative information.

This application note shows result of ATR measurements of various grease samples (before and after use), evaluating moisture, oxidation and oil-separation. Industrial grease containing urea-based thickener was used as a sample.

Figure 1. FTIR spectrometer with ATR accessory (FT/IR-4600 + ATR PRO ONE)

Experimental

| Measurement | |

| Instruments | FT/IR-4600 |

| Resolution | 4 cm -1 |

| Method | ATR |

| Detector | DLATGS |

| Accumulation | 16 times (Approx. 20 sec) |

| Accessory | ATR PRO ONE |

| Prism | Diamond |

Keywords

ATR, grease, oxidation, moisture, oil-separation, lubricant

Results

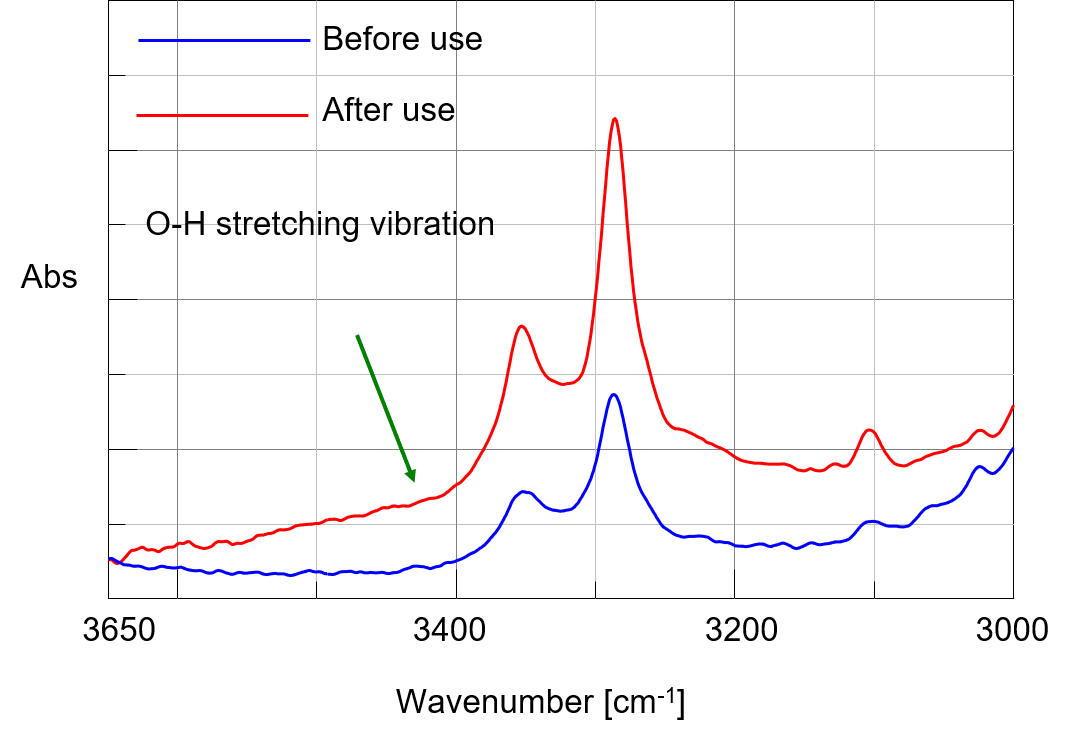

Moisture Evaluation

Figure 2 Spectra of the O-H region, showing a difference in the spectra of the grease before and after use. The broad absorption peak attributed to O-H stretching vibration (3500 – 3000 cm-1) indicates water penetration in the lubricant.

Figure 2 Spectra of grease (O-H region)

One can also evaluate the tendency of moisture absorption in the grease sample quantitatively. This requires the creation of a calibration curve using standards with known concentrations. JASCO’s Spectra Manager™ software can be used with classical least squares (CLS) calibrations as well as other chemometric techniques.

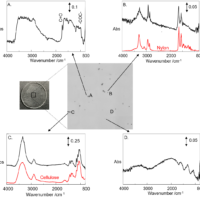

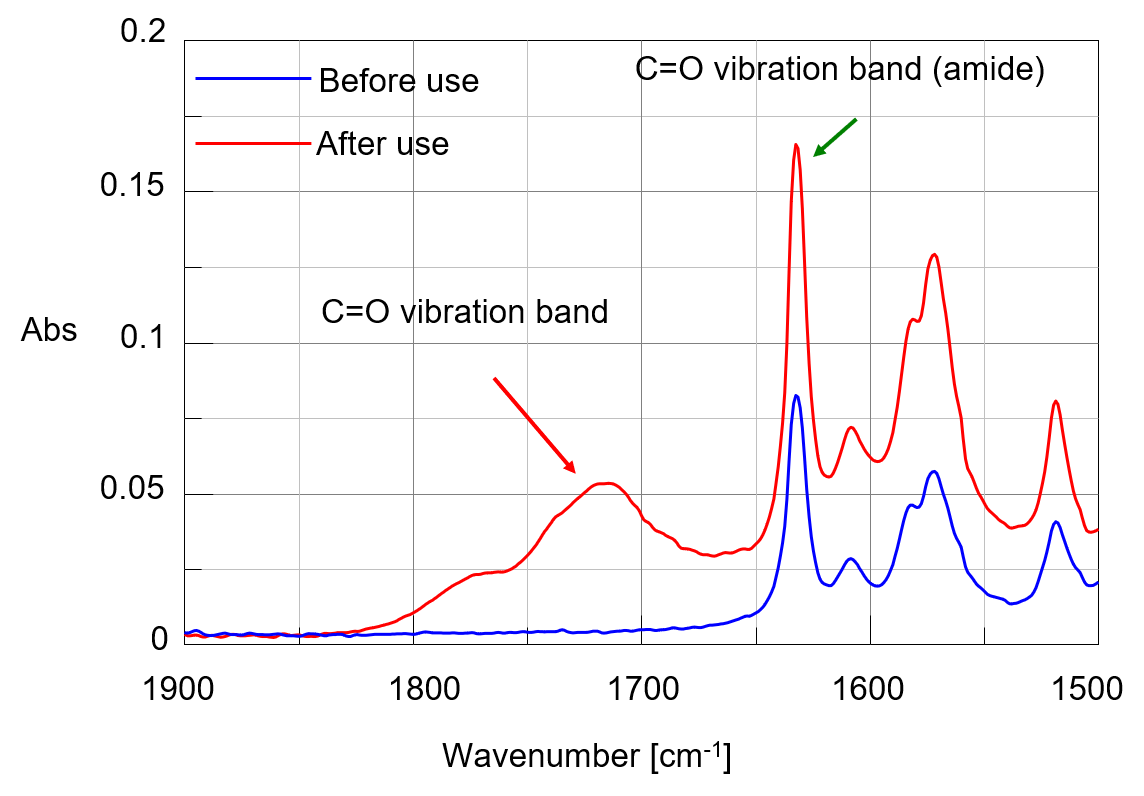

Oxidation Evaluation

Grease generally consists of a base oil, thickener, and additives. If the base oil oxidizes, carbonyl and aldehyde are generated. An increase and/or decrease of the absorption peak attributed to the C=O stretching vibration (near 1720 cm-1) can be interpreted as oxidation of the base oil. Figure 3 shows a distinct difference in the C=O region of grease before and after use. In addition, plotting the peak height or area allows the oxidation to be estimated quantitatively.

Figure 3 Spectra of grease (C=O region)

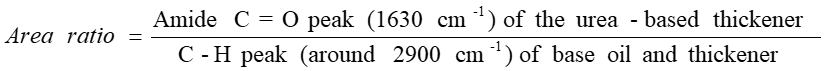

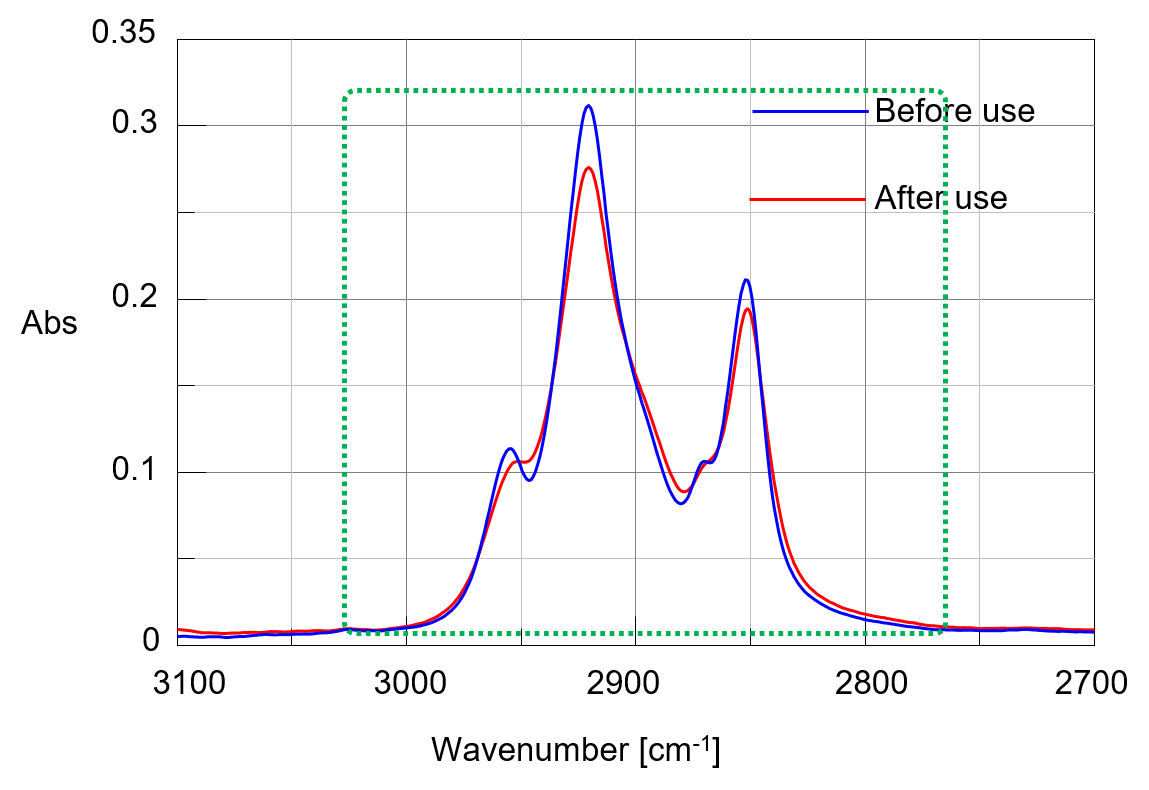

Oil-Separation Evaluation

With the movement of mechanical parts, the base oil is separated from the grease. This decreases the performance of the lubricant. FTIR spectroscopy can be used to evaluate this separation using the following formula:

The calculated result of the grease before use was 28.9, and the result after use was 16.3. These show that the base oil was significantly separated from the grease.

Figure 4 Spectra of grease (C-H region)

JASCO provides FTIR measurement using Spectra Manager™ to simplify the above evaluation methods and offers a ‘turn-key’ solution to the analyst.

Conclusion

This report demonstrates that ATR sampling can be used to evaluate lubricant performance quickly and effectively, monitoring the ingress of moisture, effects of oxidation, and oil separation before and after use.