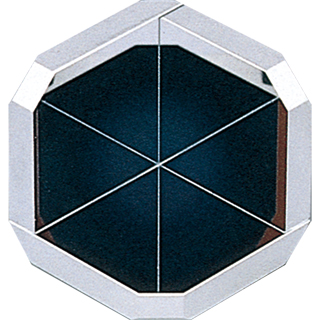

Corner-cube mirrors

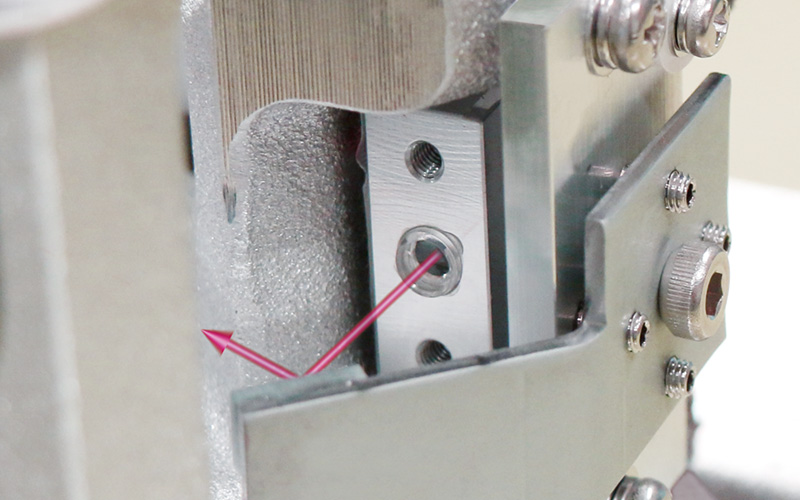

Corner cube mirrors automatically correct for any light path deviation.

Mechanism of corner-cube mirror

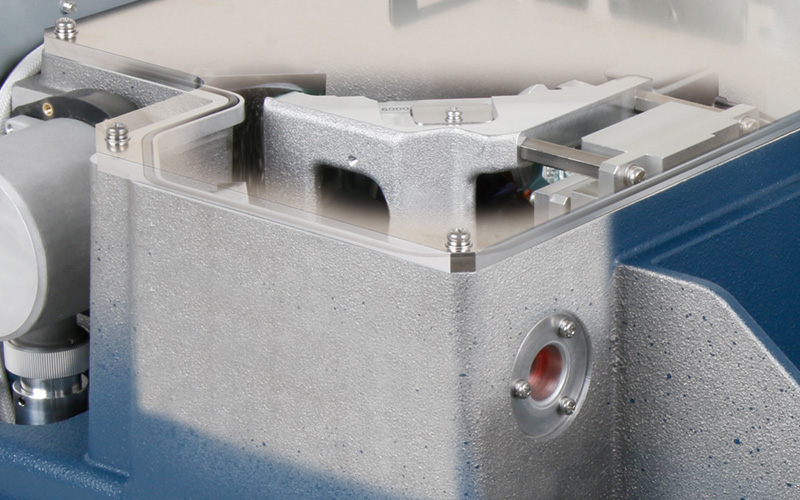

Maintenance-free design

The overnight energization and periodic replacement of desiccant to protect the optical components are not required because of the proven robust sealed interferometer. The window plate of the interferometer is made of KRS-5, which has excellent humidity resistance. In addition, a long-life diode laser is used and a corner-cube mirror is used for the interferometer mirror.

The high sealability interferometer protects the humidity-sensitive optical elements. A built-in sensor constantly monitors temperature and humidity.

The diode laser is used as a sampling laser, and it has a high wavenumber precision of 0.0005 cm-1, which is equivalent to a He-Ne laser by the XLD method.

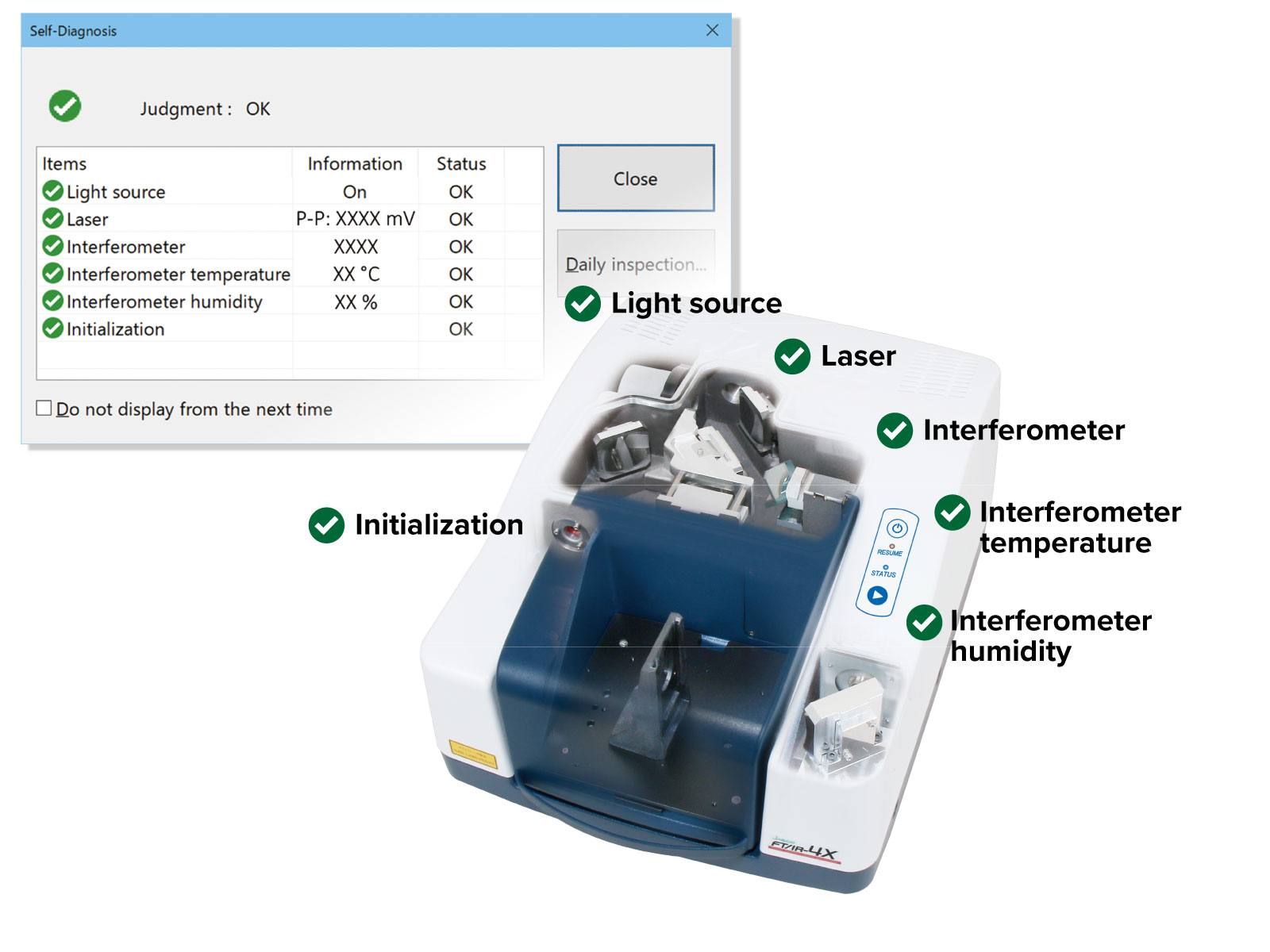

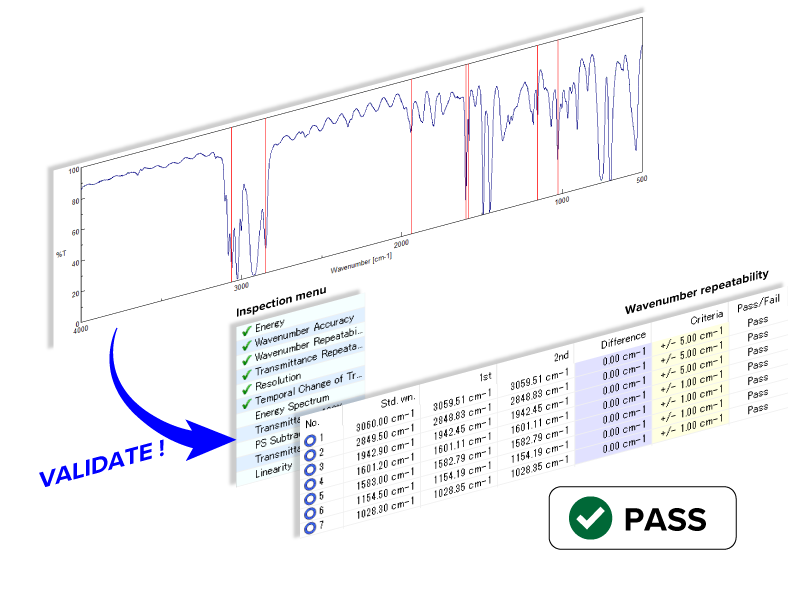

Self-diagnosis and validation

The self-diagnosis function checks the status of the FT/IR-4X at startup. If there is any problem, it will be detected immediately. The diagnosis results are automatically recorded, and it is possible to track the temporal change. Therefore, if there is a problem with the data, you can retrace and check.

In addition, FT/IR-4X is equipped with NIST traceable polystyrene film for easy validation. The status of the instrument can be checked daily and can be confirmed the reliability of analysis results.

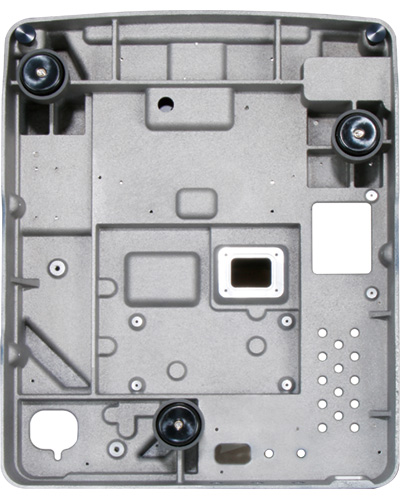

Base isolation structure

The highly rigid optical bench is manufactured from the cast aluminum with a ribbed structure. This optical bench is supported by vibration-free mounting to prevent the transmission of external vibrations.

Optical base (bottom)

Vibration-proof mounting