Equipment related

Q1. I heard that a Raman spectrophotometer is difficult to operate. Can I use it?

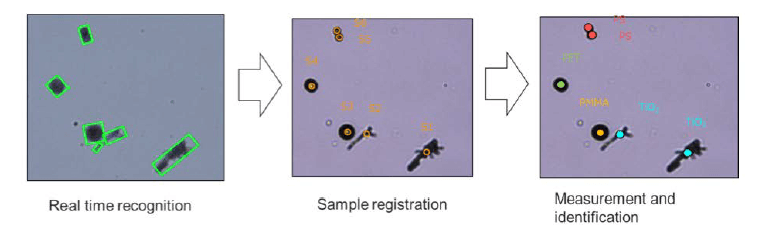

One of the most time-consuming aspects of Raman microscopy is identifying the measurement location in the sample. This can be done quickly for samples that require distribution analysis by using 2D or 3D matrices, with measurements made at fixed intervals. However, for randomly arranged samples the user has to select each position by searching the microscopic image and individually selecting the points of interest. The Sample Search function in Spectra Manager™ can be used for particulate or powder samples to automatically analyze the microscopic image and identify the position based on size, contrast and/or color of the target defined by the user. Simply click the start button to execute spectral acquisition and the stage is automatically positioned for optimized spectral measurement of all identified sample points. Measurement points can be recognized in real time, allowing simultaneous spectral acquisition and qualitative analysis. This function is recommended for foreign materials contaminating Si wafers or polymer films, powder components in pharmaceutical samples and micro-plastics.

Fig. 17 Automated sample search for particles and powder samples

Q2. What is Class 1 of the Laser Safety Standards? What are the precautions for handling?

In order to ensure safe use of lasers, they are classified according to specific standards specified in the “Safety standards for laser products”. Class 1 corresponds to a laser power of approximately 0.39 mW or less, and it is required to “prevent continuous viewing of the beam”. JASCO employs an automatic opening and closing mechanism for the sample chamber and an interlock mechanism so that the beam cannot be directly viewed, so complying with Class 1. Being able to close and measure the sample chamber prevents stray fluorescence light and helps detect weak Raman light. In addition, sample room lighting makes it easy to set up samples.

Fig. 18 Automatic opening and closing of the Raman spectrophotometer

Q3. How long does it take to measure a Raman spectrum?

If the sample produces a sufficient amount of Raman scattering, it can be set and measured within 1 minute. After turning on the power to the spectrometer, set the sample on the stage, focus while watching the sample image, and close the sample chamber door. Focus the sample so that the laser spot is small, set the measurement conditions while checking the spectrum preview, and start the measurement.

Q4. Does Raman spectroscopy destroy the sample?

Basically it is nondestructive. However, if you keep the high power laser on a small point, you may damage the sample. In general, it is recommended to use a attenuator to reduce the amount of laser irradiation to the sample and extend the exposure time.

Q5. What is the spatial resolution of Raman measurements?

The spatial resolution depends on the laser, objective lens, and the confocal aperture size. The beam spot size at 532 nm laser is as follows:

Table 2 spacial resolution for objective lenses

| Objective | Spacial resolution |

| 100x | approx. 1 μm |

| 50x | approx. 2 μm |

| 20x | approx. 5 μm |

Further details are described in “spatial resolution” in Section 2.

Q6. What does confocal optics refer to?

Laser Raman microscopes use confocal optics. A pinhole is placed at a position conjugate to the focal point of the objective, lens and light from other regions is cut off. This makes it possible to extract the signal at the focal position of the laser beam spot, enabling measurement in the depth direction.

Q7. I heard that no pre-treatment is required. Can I measure embedded samples?

The laser Raman microscope uses confocal optics and can change the focus position in the depth direction, as explained in Q6. Therefore, if you can focus on an embedded sample and perform measurements on it. Additionally, the JASCO Raman system uses dual spatial filtration (DSF) and has a high resolution of 1 μm in the depth direction.

Q8. To what depth can measurements be performed?

This depends on the working distance for the objective lens, which is shown in the table below for different lenses. Measurements can be performed at a depth of up to 10.6 mm with a 50× long objective lens.

Table 3 working distances for objective lenses

| Objective | Magnification | N.A. | Working distance |

| 100x | 100 | 0.9 | 1 mm |

| 50x | 50 | 0.8 | 1 mm |

| 20x | 20 | 0.45 | 3.1 mm |

| Long distance 50x | 50 | 0.5 | 10.6 mm |