Introduction

FTIR, non-dispersive infrared analyzer, Gas detector tube system and GC/MS are well known as methods for analyzing gas samples. In addition Gas Analysis using Quantum Cascade Laser is getting popular recently as a new analytical technique. Each of those methods has either merit or demerit actually, however, an analytical method based on FTIR has a remarkable merit such as quick analysis of multiple gas components without any pre-treatment. As examples of FTIR analysis, there are actual applications as ‘Monitoring Green House Effect gas’, ‘Quantitative/ Qualitative gas analysis at the fire site’ and ‘Quantitative analysis of moisture content inside of gas cylinder’.

In case of practical measurement of low concentration gas by using FTIR, a long pathlength gas cell needs to be mounted inside of sample compartment of FTIR for measurement. By using a conventional gas cell, measurement throughput was in many cases very low and it was necessary to use MCT detector which needs liquid N2. However, JASCO’s 12M long pathlength cell with optimized optics allows higher measurement throughput and enables to measure gases with lower concentration than ppm level using TGS detector*1). There are 3 different types of gas cell such as glass type cell, stainless type cell and full vacuum type cell depending on each purpose. Detailed features of each cell are described as below.

*1) Lowest measurement limit depends on each gas component.

FTIR gas analysis system

Features of cells

Glass type cell (12 M)

- Body material is made of glass for reasonable price.

Stainless type cell (12 M)

- Pressurization up to +0.1 MPa

- Heating up to 70ºC as option

- Heating cell up to 200ºC as option

Full vacuum type cell (12 M)

- For full vacuum system of FT/IR-6000 series

- High sensitive and precise measurement of water vapor, carbon dioxide gas because of full vacuum condition

Figure 1. Gas cells (left: glass type, center: stainless type, right: full vacuum type)

Experimental

Glass type cell

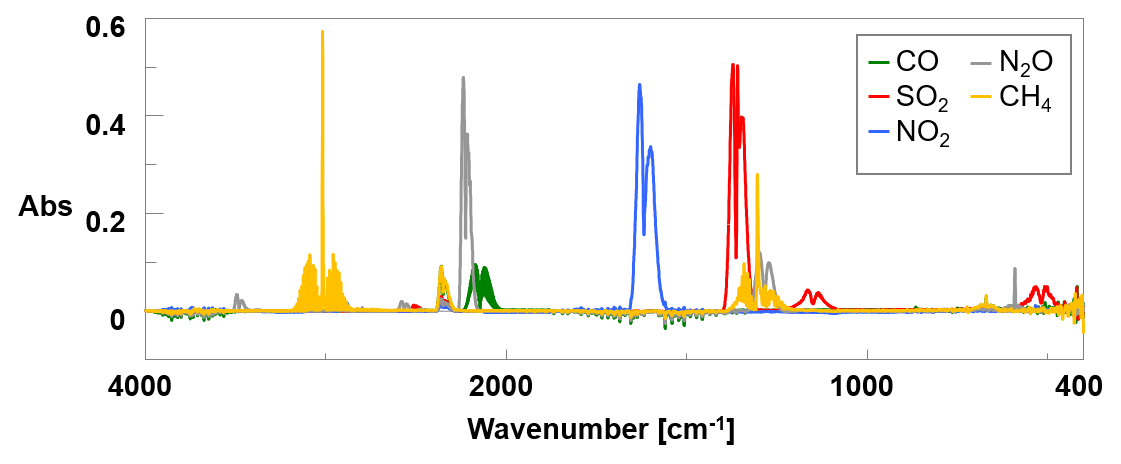

Figure 2 shows measured spectra of CO, SO2, NO2, N2O, CH4. In gas analysis application using FTIR, it is possible to execute simultaneous quantitative analysis of multiple gas samples which have each peak in different wavenumber.

Figure 2. IR Spectra of each gas component

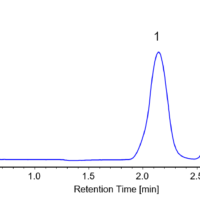

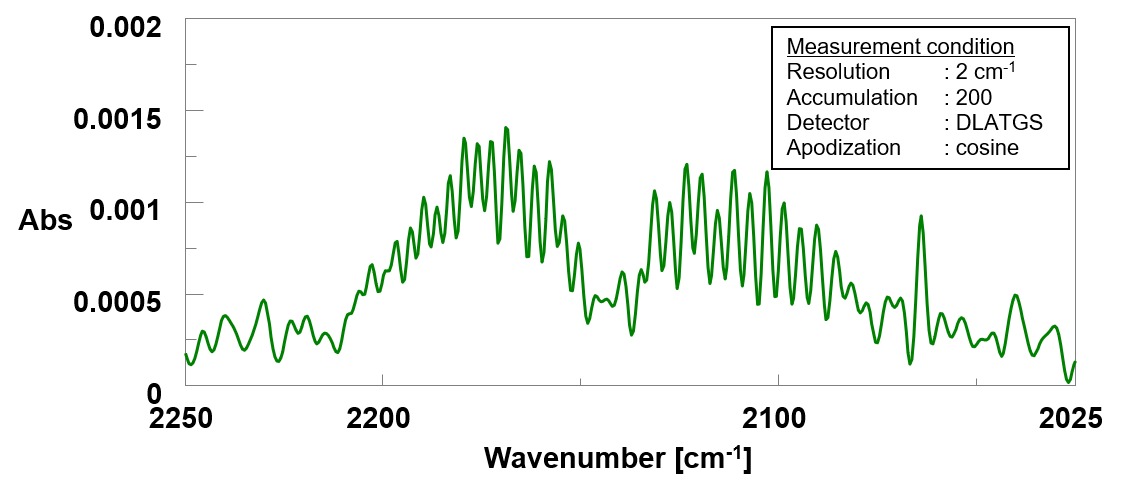

Figure 3 shows spectrum of CO gas of 530 ppb with DGS detector.

Figure 3. IR spectrum of CO gas (530 ppb)

Stainless type cell

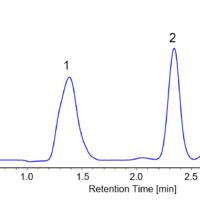

Figure 4 shows IR spectrum of CO gas under both atmospheric pressure condition and pressurized condition. Peak intensity in case of pressurized measurement is 2 times larger in proportion to the pressure, which makes it possible to measure low concentration gas in ppm level.

Figure 4. IR spectra of CO gas

Full vacuum type cell

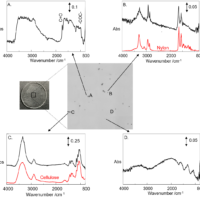

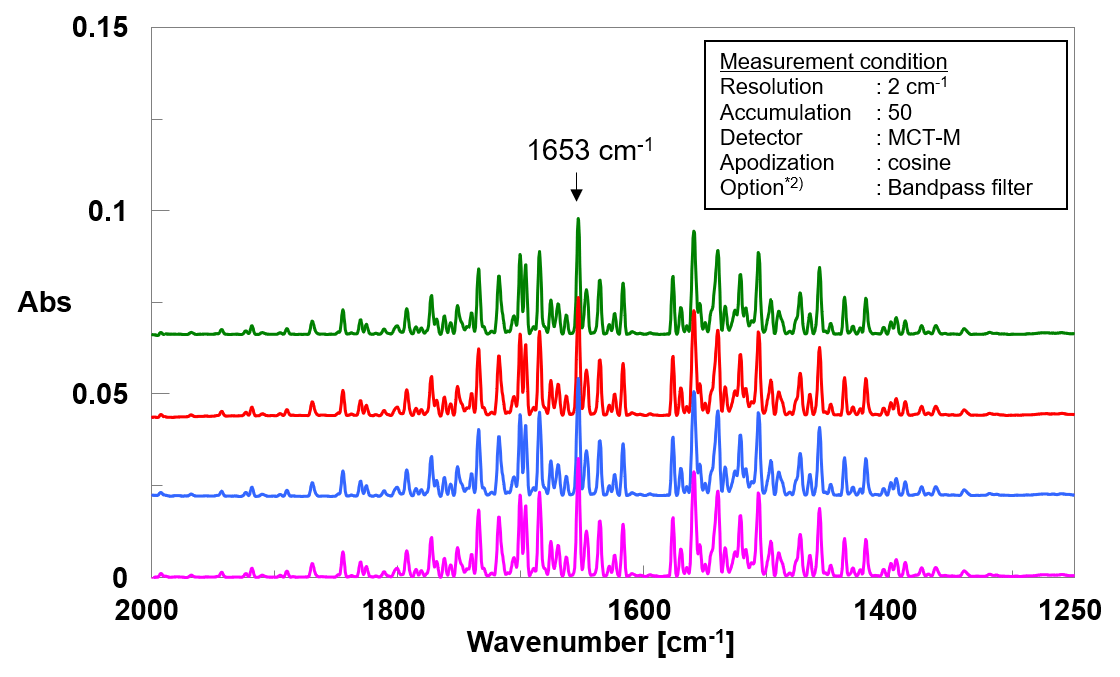

It is confirmed that how much water vapor affects the peak intensity through repeated measurement of standard 15 ppm water vapor and its result is shown in Fig. 5. Actual measurement procedure in this experiment was to inject standard water vapor gas into gas cell, to measure and to exhaust repeatedly. As a result, peak intensity in 1653 cm-1 obtained was as precise as 0.0316 (Abs) +/- 0.63%, which shows that water vapor in atmosphere didn’t affect the measurement and analysis.

Figure 5. IR spectra of water vapor (repeated measurement)

*2) Option system with bandpass filter and MCT detector enables high sensitivity measurement, but it is necessary to select the proper bandpass filter depending on the target gas.