Introduction

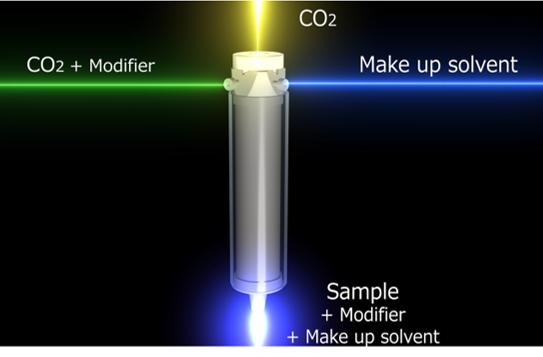

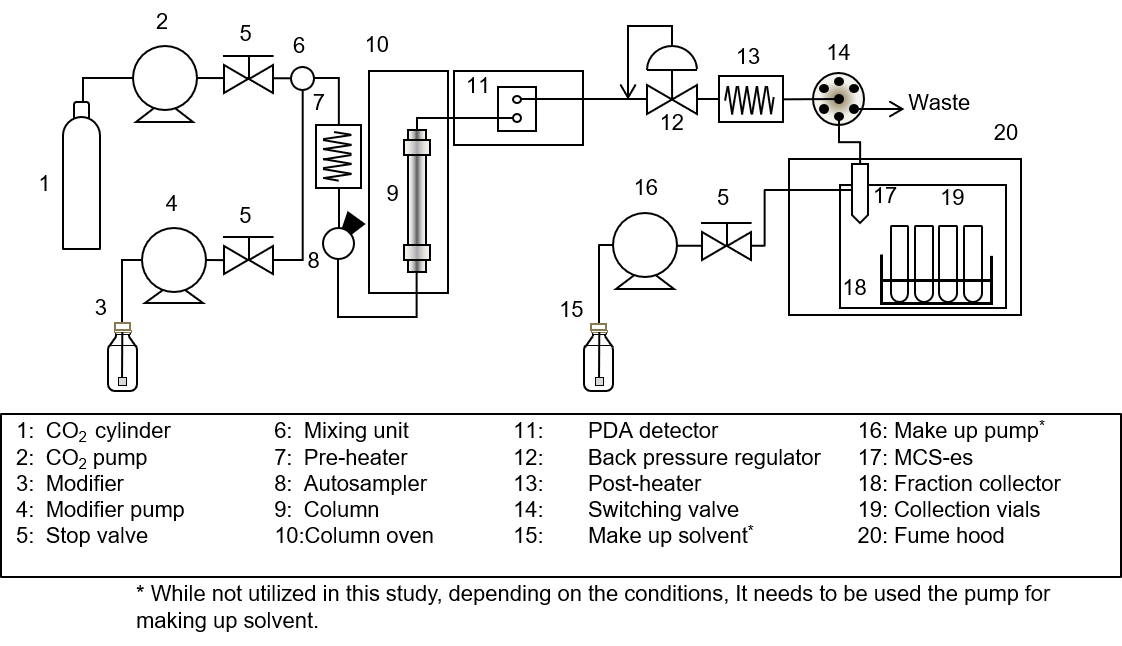

Preparative separation by supercritical fluid chromatography (SFC) offers several advantages. It allows for higher throughput compared to HPLC, and the primary solvent of mobile phase, CO2, becomes a gas upon recovery, making post-processing, such as evaporation and drying, easier. Furthermore, the CO2 is cost-effective compared to organic solvents, and it can be obtained in high purity (>99.99 %).On the other hand, supercritical CO2 undergoes an adiabatic expansion approximately 500 times when it is released to atmospheric pressure at the outlet of the back pressure regulator. Consequently, during preparative separation, it is necessary to take measures to prevent contamination such as condensed water caused by scattering of the sample and sudden temperature drops. On this note, by installing MCS-es, a gas-liquid separation nozzle, on the Z-axis arm of the Gilson 223 Sample Changer, we were able to slowly collect only the liquid while preventing scattering and condensation due to CO2 expansion. Furthermore, this allowed for efficient preparative separation with high recovery rates over a wide flow range. It’s also possible to pour make up solvents directly into MCS-es (patent pending).

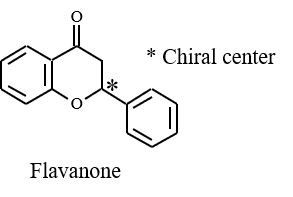

In this study, we report the chiral preparation of warfarin using the LC-4000 series UFC (Unified Fluid Chromatograph) Prep-SFC-M system in combination with the MCS-es.

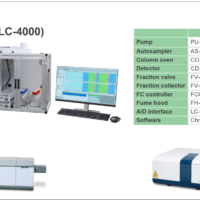

LC-4000 Semi-prep SFC system

Experimental

Instruments

CO2 pump: PU-4387

Modifier pump: PU-4087*

Pre-heater: HE-02

Heater controller: HC-4068-01

Autosampler: AS-4358

Column oven: CO-4060*

PDA detector: MD-4010*

BP regulator: BP-4340

Post-heater: HE-02

Heater controller: HC-4068-01

Make up pump: PU-4086*

Fraction valve: FV-4000-06

Fraction collector: Gilson 223

Sample Changer

Fume hood: FH-4388

* with option units

Gilson 223 Sample Changer + MCS-es

Image of collection by MCS-es

Conditions

Column: CHIRAKPAK IA (20 mmI.D. x 250 mmL, 5 µm)

Eluent: Carbon dioxide/methanol (60/40)

Flow rate: 50 mL/min

Column temp.: 35 ºC

Wavelength: 200-400 nm, 230 nm (CH1)

Back pressure: 10 MPa

Post-heat temp.: 60 ºC

Inj. volume: 1000 µL

Standard: Warfarin 5000 µg/mL in methanol

Schematic Diagram

Keywords

Semi-prep SFC, Supercritical carbon dioxide, gas-liquid separator, MCS-es, fraction collector, Gilson 223 Sample Changer, CHIRALPAK IA, chiral preparation

Results

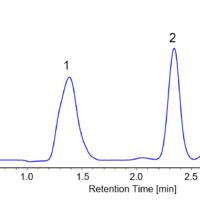

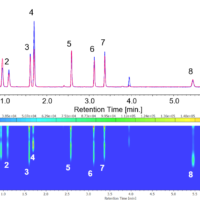

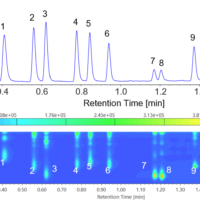

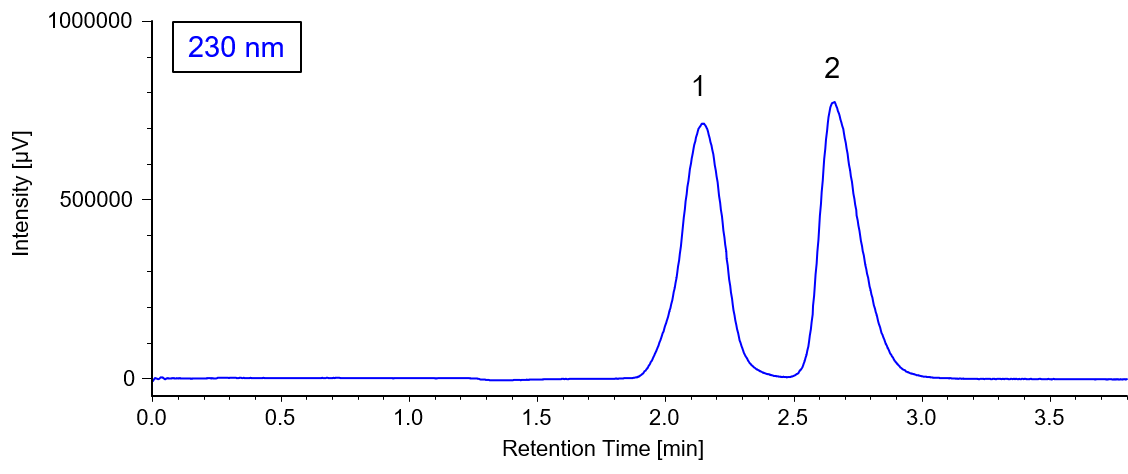

Figure 1 shows a chromatogram of a warfarin standard solution. Based on this chromatogram, a collection method was made and used for preparative separation.

Fig.1 Chromatogram of warfarin standard solution

1: Warfarin tR-1, 2: Warfarin tR-2

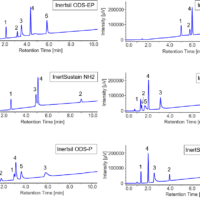

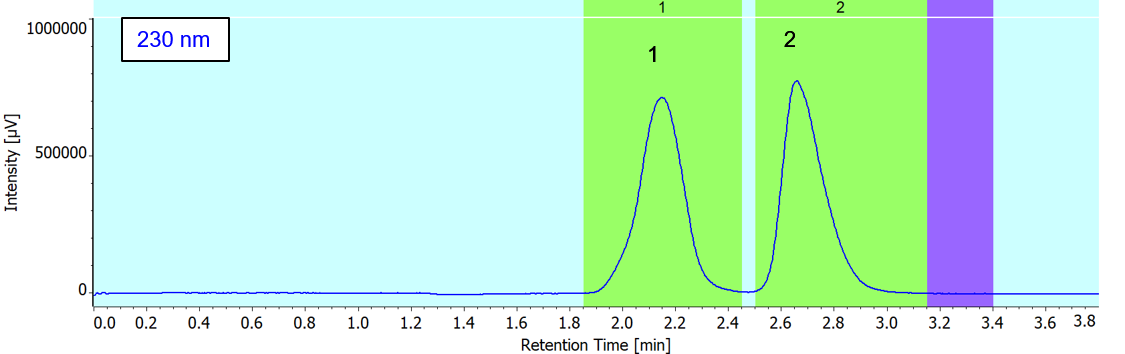

Figure 2 shows the collection results of warfarin based on time fractionation, and Figure 3 shows the chromatogram obtained by re-measuring each fraction. The yellow-green section in Figure 2 represents the collection phase, while the purple section indicates the drop waiting time*1.

*1 Time taken to collect the modifier and makeup solvent remaining in the MCS-es after valve switching.

Fig.2 Collection results of warfarin

1: Warfarin tR-1, 2: Warfarin tR-2

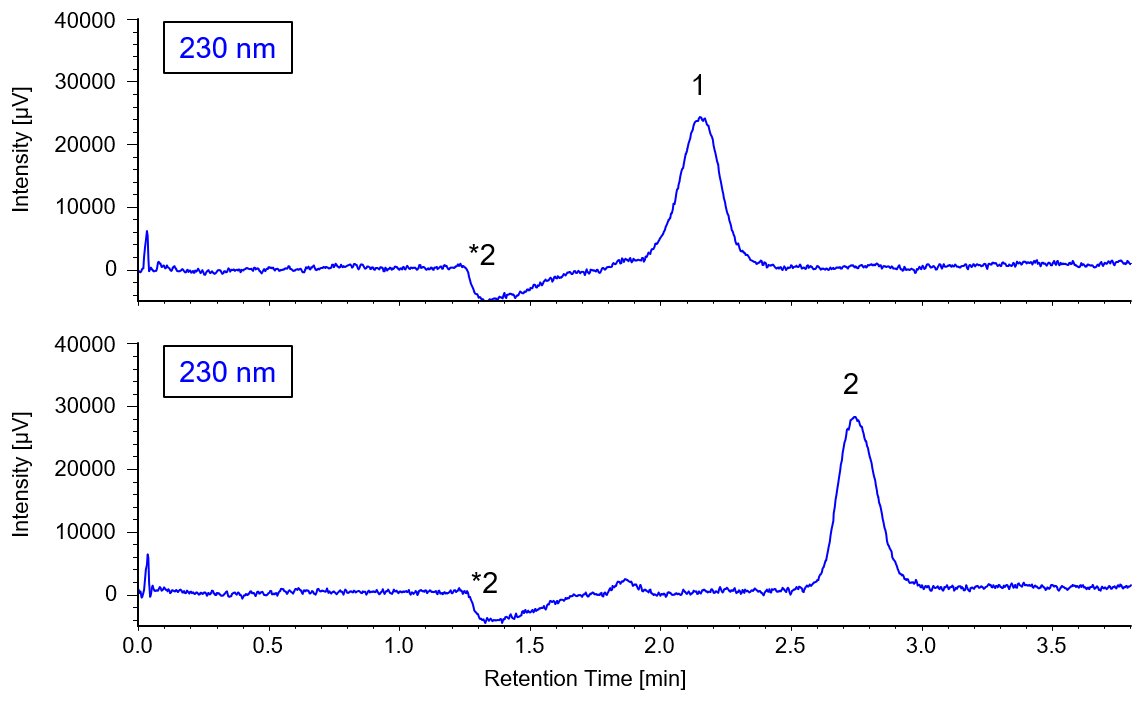

Fig.3 Chromatograms obtained by re-measuring each fraction

1: Warfarin tR-1 (equivalent to 100 µg/mL), 2: Warfarin tR-2 (equivalent to 100 µg/mL) *2 Solvent peak

Each fraction was diluted to 25 mL by co-washing with methanol so that the concentration of warfarin tR-1 and warfarin tR-2 was 100 ug/mL each (equivalent). These solutions were used for recovery rate measurements. Table 1 shows the recovery rates for each component, calculated assuming the area values at the time of measurement of the warfarin standard solution as 100% (total 200 µg/mL, 100 µg/mL for both tR-1 and tR-2). Excellent recovery rates were obtained for all components.

Table 1 The recovery rates of each component of warfarin

| tR-1 | tR-2 | |

| Recovery rate [%] | 93.04 | 97.58 |

Conclusion

The use of the Prep-SFC-M system in combination with MCS-es successfully achieved chiral preparation of warfarin with excellent recovery rates.

MCS-es can be used with a maximum total flow rate of up to 200 mL/min (under specified conditions). It also supports preparation at relatively low flow rates on an analytical scale, so it can be applied to preparation over a wide range of flow rates.