Introduction

UV curing resin is generally used for a paint, ink, and in the fields of coating technology. Moreover, it is broadly used for photo lithography etc. also in the semiconductor industry. UV curing resin is an environment-friendly and clean material as compared with thermosetting resin, and it is expected also to have the superior performance and productivity, such as short-time hardening. Evaluation of the performance of UV curing resin is now getting very important in improvement in productivity, or development of new material. FTIR is an effective technique of evaluating the reaction velocity in the hardening process of UV curing resin. This article explains solution examples for hardening process monitoring of UV cured resin.

Experimental

Figure 1 shows an external view of the hardening process monitoring system of UV curing resin. There are some UV curing resins whose hardening process ends in about several seconds and therefore, the rapid scan which allows the measurement at intervals of fastest 50 msec. is suitable for measuring such a reaction. In addition to the rapid scan, MCT detector with fast response time is employed in this system. Moreover, for detecting a key band with high sensitivity, the filter for high sensitivity measurement can be attached to this system as an option. This system can obtain an infrared spectrum with a reflection method, where a sample can be placed horizontally, assuring easy sampling (Figure 1 right).

Figure 1. The hardening process monitoring system of UV curing resin

In this system, UV light is irradiated from the upper part of a sample by connecting a fiber and in addition, the sample compartment can be monitored by an optional oxygen meter. In a radical polymerization process, this system enables to evaluate close relationship of the oxygen which disturbs the hardening of resin.

Acrylate UV curing resin was applied to the stainless steel substrate, and was measured under the conditions as follows. The sample was irradiated with UV light about 4 seconds after the measurement starts. Moreover, the difference in the reaction by the existence of oxygen was investigated by carrying out the nitrogen purge.

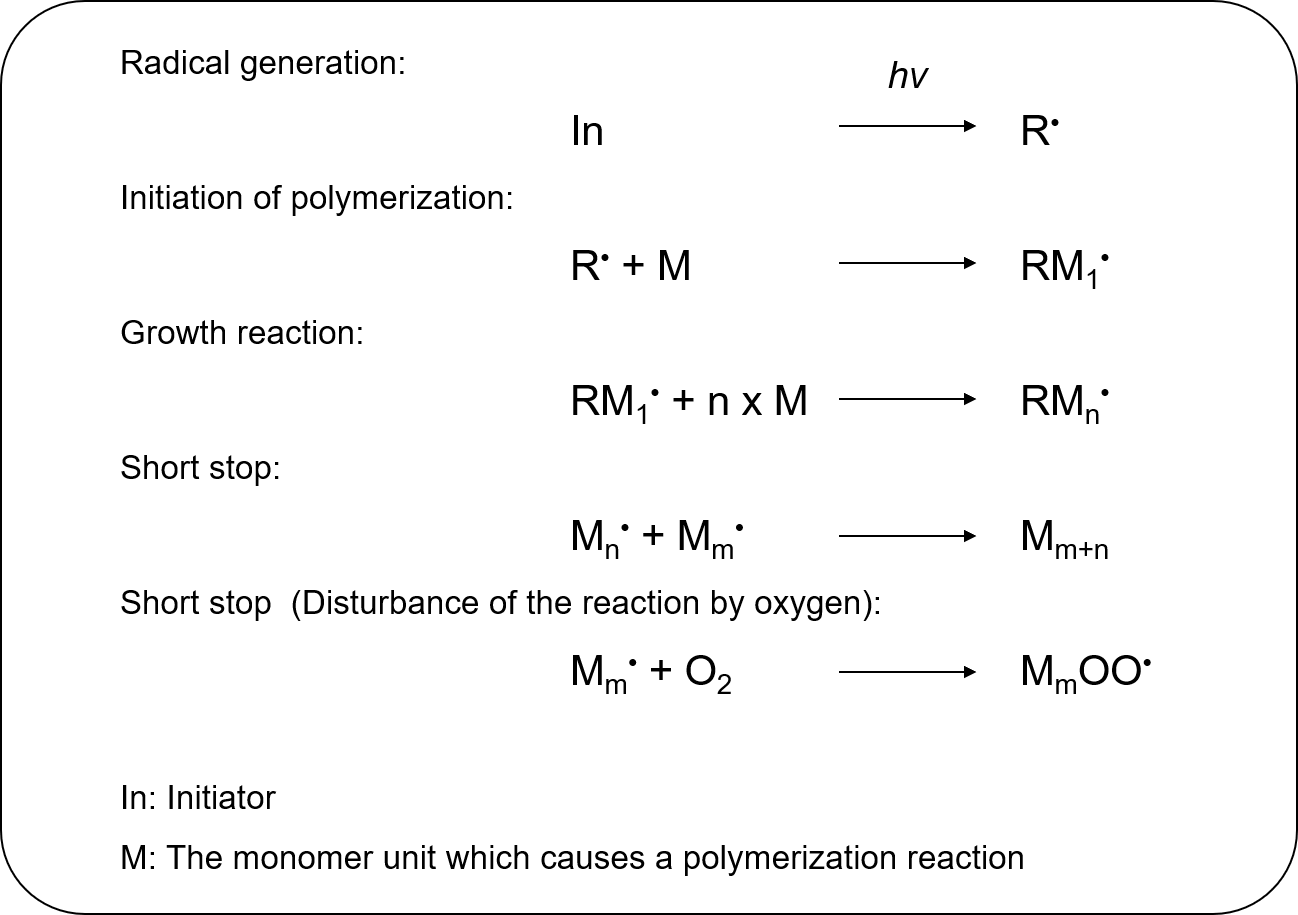

Figure 2. Radical polymerization

Measurement conditions

Measurement method: Reflection

Detector: MCT-M

Filter : 2000 to 0 cm-1

Mode : Rapid scan

Scan speed: 32 mm/sec

Time: 65 sec.

Interval : Approximately 75 msec.

Resolution : 4 cm-1

Accumulation: 1

UV source : Hg-Xe lamp

UV output: 290 mW/cm2

UV irradiation : 4 seconds after the measurement start

Results

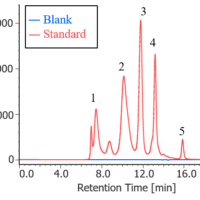

Figure 3 shows spectra of UV curing resin before and after irradiation with UV light.

Figure 3. The spectra of UV cured resin before and after irradiation of UV light

It is clearly confirmed that a spectrum changed significantly after irradiation of UV light. Since the reaction of acrylate UV cured resin is processed with a radical polymerization in this case, the attention is generally paid to the peak in 1650-1600 cm-1 which is ascribed to C=C, and 820-790 cm-1 which is ascribed to C=C-H. This time the peak in 820-790 cm-1 was observed.

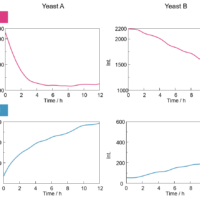

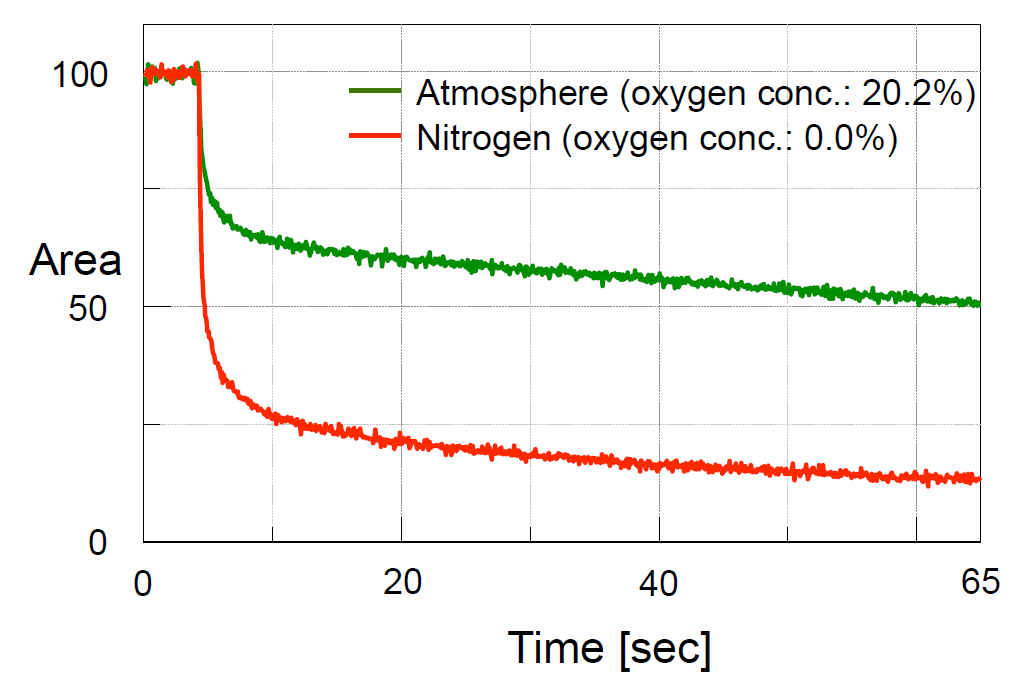

Figure 4* illustrates the peak area changes under nitrogen and atmosphere environment respectively.

Figure 4. Difference between the peak intensity of the 810 cm-1 with or without nitrogen purge

(* The vertical axis was normalized in order to make an intensity change to be easily compared.)

It is assumed that the reaction of the sample under nitrogen started immediately by irradiation of UV light for hardening of resin. On the other hand, when a sample is irradiated with UV light under atmosphere, it is assumed that a reaction started also immediately after irradiation, but right after a reaction became slower by the polymerization prevention by oxygen. As explained, the polymerization prevention by oxygen can be evaluated by this system as well as the monitoring of hardening process of UV cured resin. Furthermore, this system will be effective for the evaluation of the materials whose polymerization process is hardly disturbed under atmosphere, and for the evaluation of the difference in the hardening process of the material by the polymerization initiator. Moreover, this system is applicable also to evaluation of cationic polymerization or hybrid UV hardening material.