Introduction

In IR spectrometry, the ATR method has been widely used because of simple measurement procedure which does not require the pretreatment of sample. In most of commercially available ATR accessories, the ATR crystal can contact with sample by operating the sample presser manually. In the ordinary sample presser, the pressure limiter mechanism for avoiding the breaking of crystal has been implemented. Recently, the demands that the users want to control the contact pressure of ATR accessory exactly are increased.

Auto contact ATR function with the auto driving mechanism of sample presser makes it possible to change the contact pressure stepwise as well as to avoid the breaking of crystal. In addition, the auto contact ATR function can offer exactly the same contact pressure at every measurement so that any operator can obtain quickly the IR spectrum highly reproducible. In this article, the capability to change the contact pressure stepwise was applied to the measurement of food supplement. Also the simulation for applying to acceptance inspection was performed.

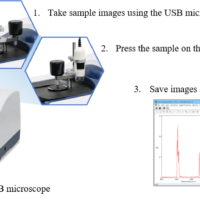

Figure 1. Versatile FTIR with auto contact ATR

Auto contact ATR

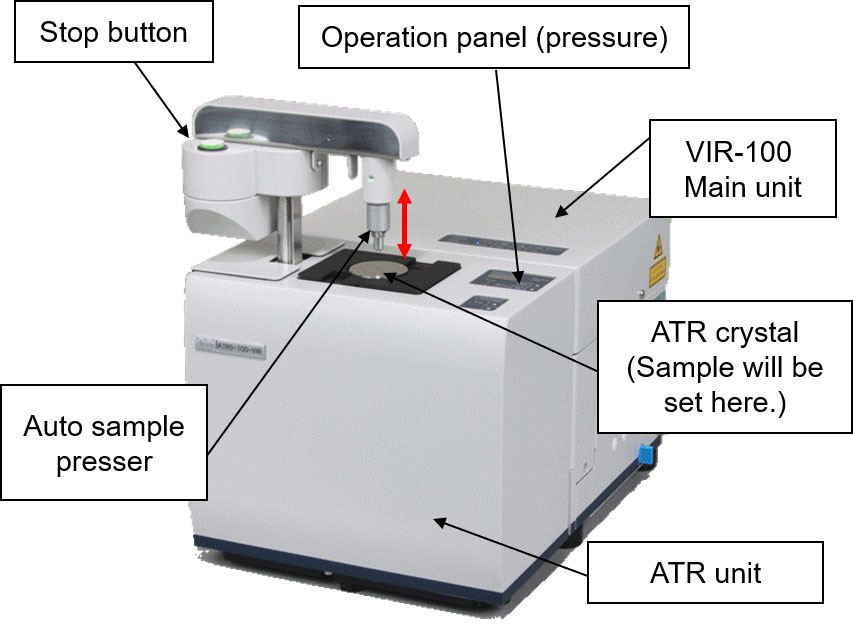

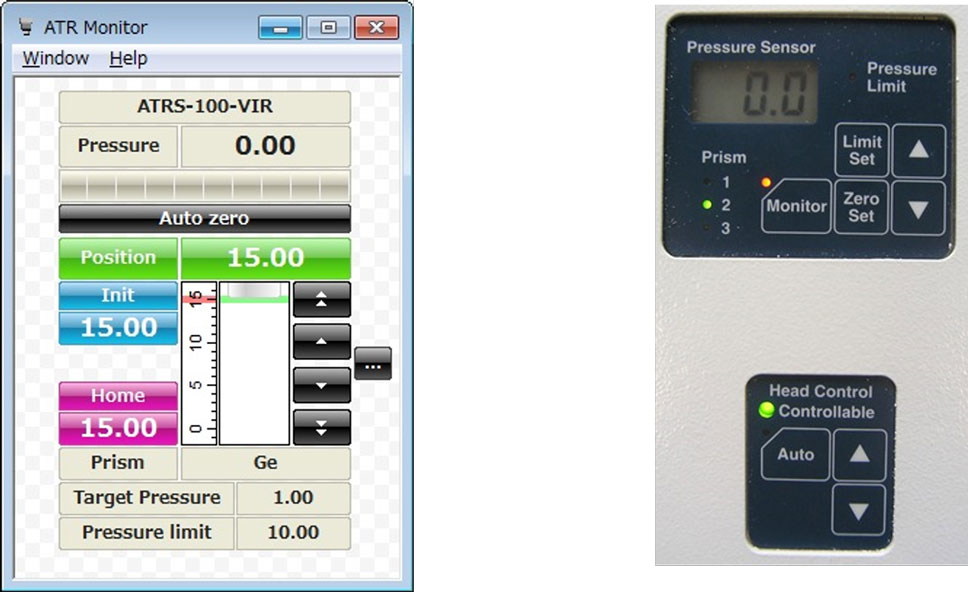

The auto contact ATR function including auto drive mechanism of sample presser enables to control the contact pressure to be applied to the sample by the built-in pressure sensor. The drive of auto sample presser can be controlled through the operation panel on the accessory or through the PC software (Figure 2).

Figure 2. Pressure monitor (left) and operation panel (right)

In both cases, you can set the proper contact pressure by observing the preview spectrum of sample. In addition, the sample measurement procedure such as “contact with sample”, “measurement” and “release of sample” can be preprogrammed so that you can complete one sequence of measurement procedure just by pushing the start button. Such automation capability may help the users for reducing their workloads on routine analysis requiring a number of similar samples.

Experimental

Measurement conditions

Resolution: 4 cm-1

Method: ATR (crystal: ZnSe)

Detector: DLATGS

Accumulation: 16 times

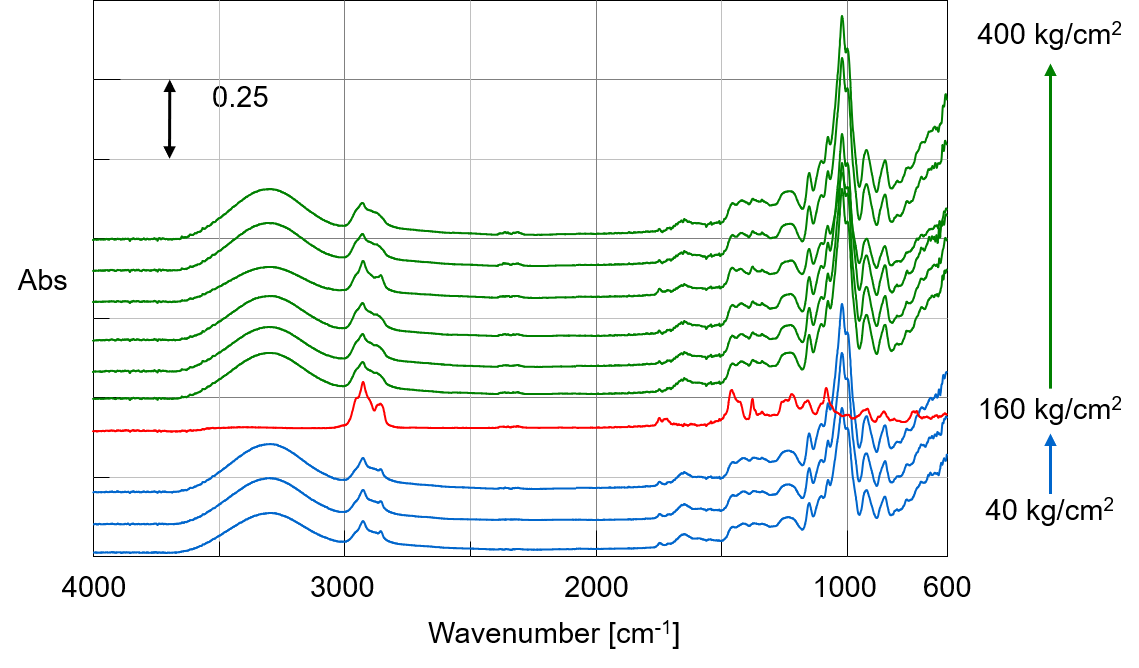

Contact pressure (based on area of crystal): 40 – 400 kg/cm2(Figure 3), 400 kg/cm2 (Figure 4 and 5)

Results

Application to brittle sample such as soft capsule of food supplement

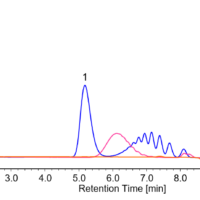

Auto contact ATR was applied to the measurement of soft capsule of food supplement. By changing the contact pressure from 40 kg/cm2 to 400 kg/cm2 at every 40 kg/cm2 step, the IR spectrum of each step was obtained (Figure 3).

Figure 3. IR spectra of soft capsule of food supplement

The IR spectrum of starch was observed in the spectra from 40 to 120 kg/cm2 and this indicates that the soft capsule was not broken at up to 120 kg/cm2 so that the starch that is the ingredients of capsule itself was observed. At the spectrum of 160 kg/cm2, tocopherol peaks appeared. These results suggest that the capsule was broken at this pressure and, the ingredients inside of capsule such as tocopherol was observed accordingly. At 200 kg/cm2 or higher pressure, it is assumed that the ingredients inside of capsule was pushed out of crystal surface and therefore, the ingredients of capsule itself such as starch appeared again. By using the auto contact ATR, such an dynamic analysis of soft capsule can be performed at one sequence of measurement pre-programmed.

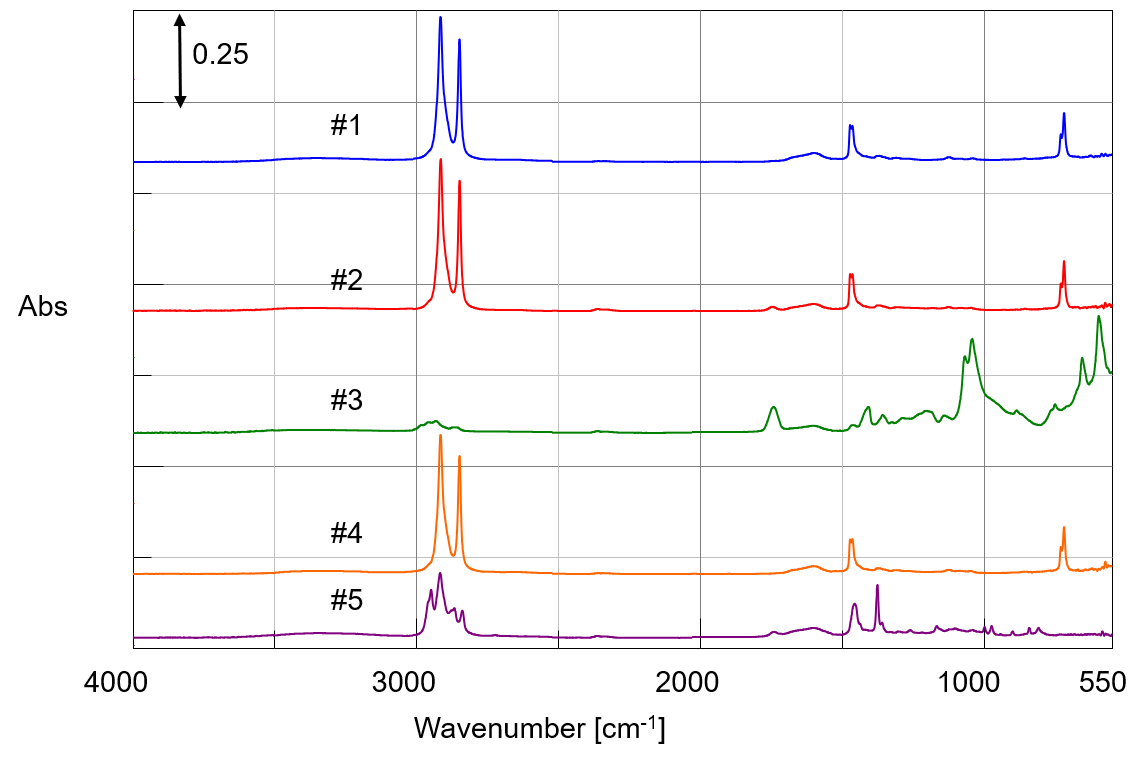

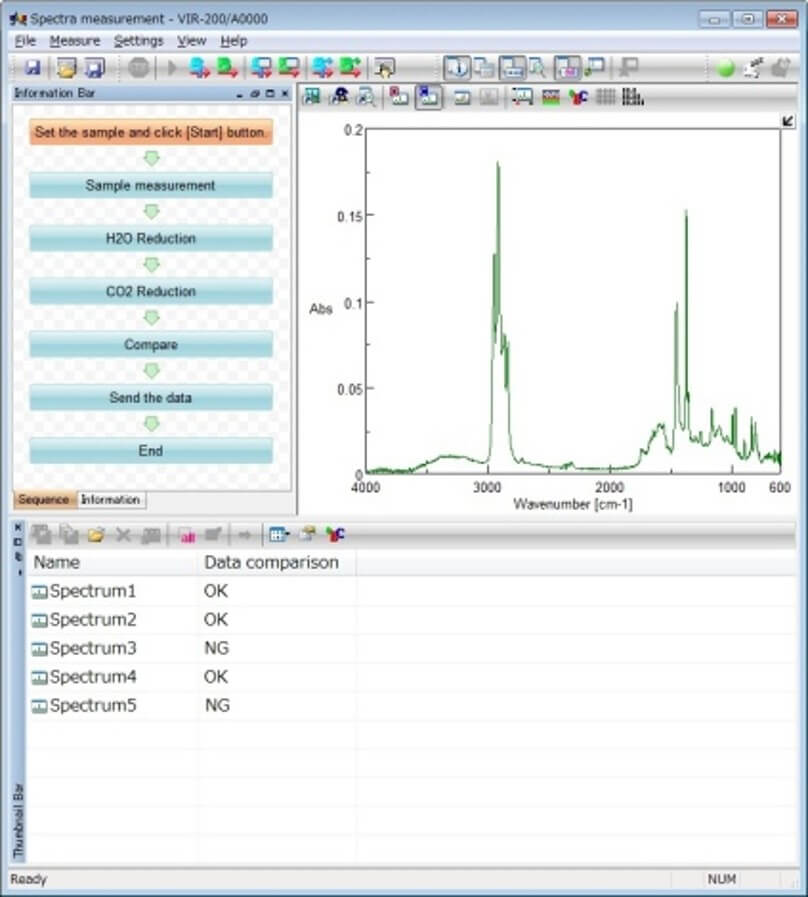

Simulation for applying to acceptance inspection

In order to simulate the acceptance inspection, the five polymer films having intentionally two different compounds from the other three standard (polyethylene) films were prepared and the IR spectra were obtained (Figure 4.). In addition to the auto contact ATR, “repeat measurement” and “judgment of acceptance” (Figure 5.) programs that are all standard functions in Spectra Measurement for VIR series, were used so that you can perform repeatedly the measurement routine including the judgment by pressing the start button.

Figure 4. IR spectra of five polymer samples

Figure 5. Judgment of acceptance

The different polymers from the standard polyethylene were easily detected as shown in Figure 4 and 5 (spectrum #3 is of polyvinylidene chloride and, the spectrum #5 is of polypropylene.).

As we demonstrated, the auto contact ATR offers the highly reproducible IR spectrum. It is also expected to apply this technique to monitoring of production line by a combination with autosampler system.