Introduction

Common additives in soft drink include caffeine, aspartame, benzoic acid, and acesulfame-K. Quality control demands to determine these additives. HPLC has been used for this analysis. An increase in the number of samples to be measured requires high-throughput analysis.

In order to meet this requirement, we have applied UHPLC system equipped with a 2 µm packing column to the analysis of these additives using high-pressure gradient method.

LC-4000 UHPLC system

Experimental

Chromatographic conditions

Column: X-Presspak C18S (2,1 mm I.D. x 50 mm, 2 µm particles in dianeter)

Column temperature: 40 °C

Mobile phase: A=50 mM NaH2PO4(pH3.6), B=CH3OH

Gradient condition (A/B): 0 min (90/10) -> 1.5 min (50/50) -> 2.0 min (50/50) -> 2.05 min (90/10)

Flow rate: 0.6 mL/min.

Detection wavelength: 214 nm

Pressure: 32 MPa to 41 MPa

Soft drink is degassed and filtered with 0.45 µm membrane filter. A portion of 1 µL is injected.

Results

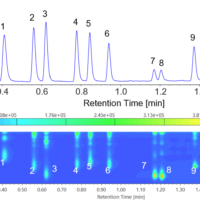

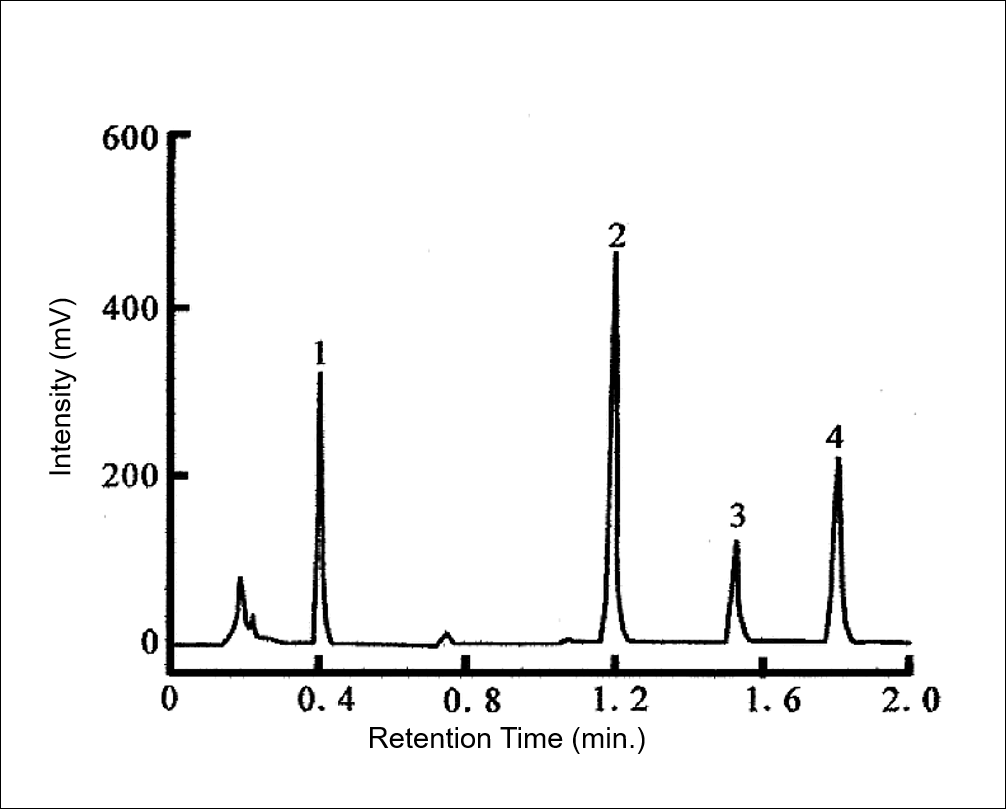

Figure 1 shows the chromatogram of standard mixture of additives. Each component is sufficiently separated. The analysis time is within 2 minutes. UHPLC enables to shorten the analysis time significantly, leading to high-throughput analysis and to reduce consumption of solvent.

Figure 1 . Chromatogram of the additives in soft drink (1=caffeine, 2=aspartame, 3=benzoic acid, 4=acesulfame K)