Introduction

Defective products may be generated due to contamination of foreign materials in the manufacturing process of industrial products. FTIR analysis is widely used for foreign material analysis to identify the cause. If there is only one kind of foreign material, it is easy to identify the ingredient by using macro ATR*. However, if foreign materials contain many kinds of components, macro measurement is not suitable to identify the component because the spectrum which includes the multi-components is obtained. In this case, the imaging measurement using infrared microscope is effective. In the imaging measurement, the measurement area can be divided finely into a grid and the spectrum of each point can be obtained. This technique can divide to each component spatially, and makes it easy to identify the components. In addition, creating a chemical image enables to give the spatial distribution of components which are not known from the observation image.

This application note shows the good result of analysis of mixed foreign materials adhering to rubber packing by using multi-channel FT-IR microscope, which has capability of high speed imaging measurement.

* FT/IR application data 130-AT-0244

Experimental

The foreign material adhering to rubber packing was sandwitched with KBr plates and pressed, then imaging measurement was performed. (KBr plate method)

<Measurement Condition>

Instruments: FT/IR-6600 + IRT-7200 Accumulation: 10 times

Detector: Linear array detector Measurement mode: Transmission

Resolution: 8 cm-1 Measurement area: 600 x 400 µm

Measurement time: Approx. 4 minutes

Results

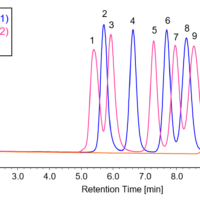

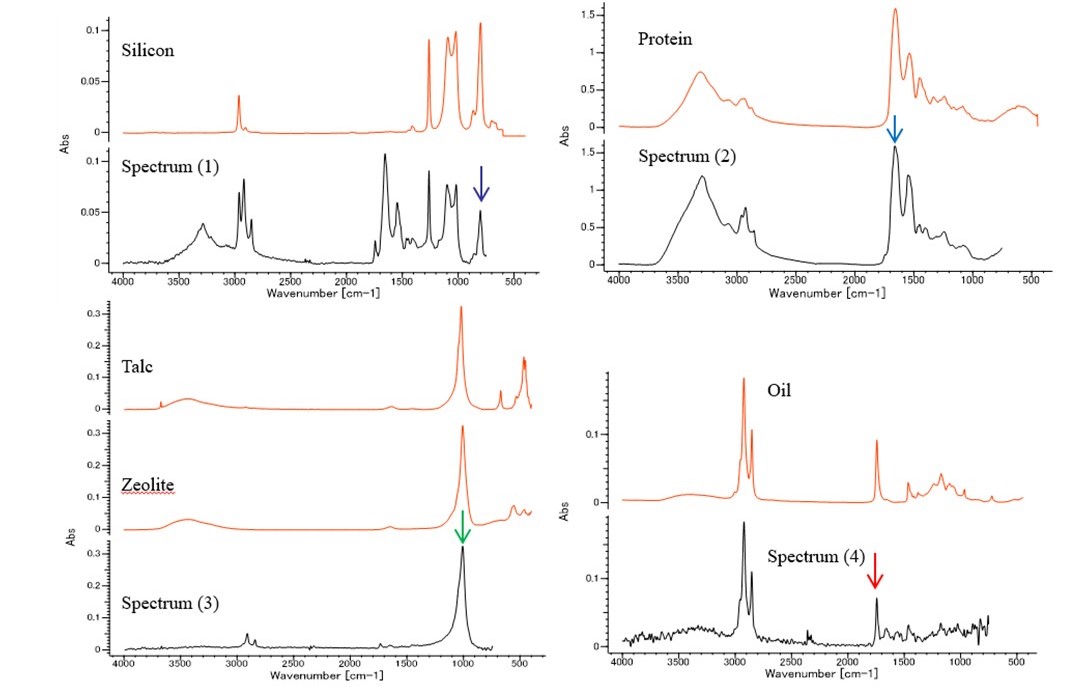

Figure 1 shows the spectra obtained by imaging measurement. From the results of imaging measurement, four different types of spectra were obtained on the different measurement position. The components were identified based on the spectra obtained. (1) is considered to be the mixture of silicon and protein from the peak around 1260 cm-1 (Si-CH3 bending vibration), the peak in 1000-1100 cm-1 (Si-O), the peak near 800 cm-1 (Si-C), the peaks around 1650 cm-1 and 1550 cm-1 (amide I and amide II). (2) is considered to be protein from amide I, amide II and the peak near 3300 cm-1 (N-H). (3) is considered to be zeolite (aluminosilicate) or talc (magnesium hydroxide and silicate) from the peak near 1020 cm-1. (4) is considered to be oil from the peak near 2940 cm-1 (C-H stretching vibration) and the peak near 1750 cm-1 (C=O).

Figure 1 Representative spectrum at each site of mixed foreign matter and database search results

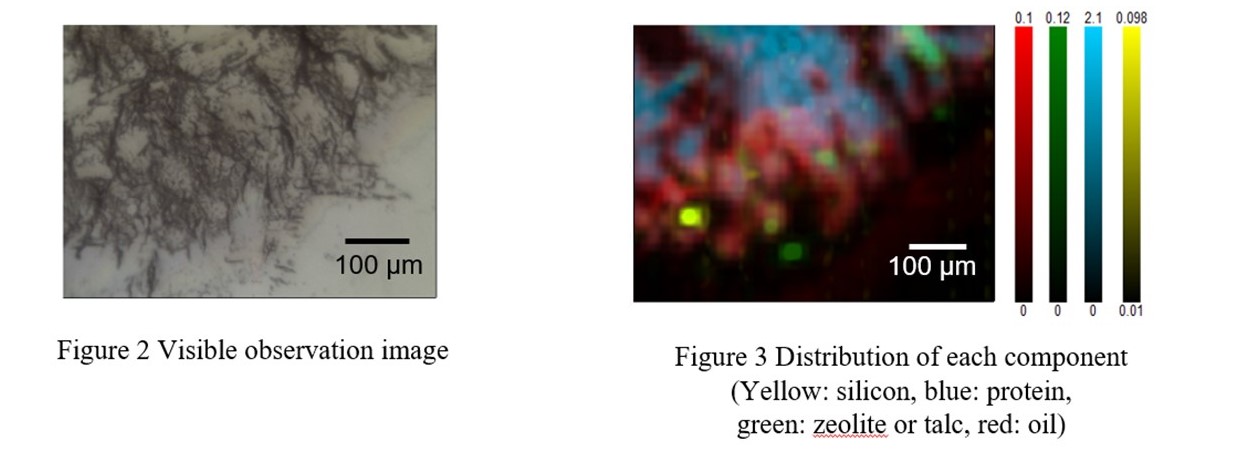

Figure 2 shows the visible observation image, and figure 3 shows the chemical image created with the peak height of the key band of each component indicated by the arrow in figure 1. From the chemical image, it was found that most of the foreign materials are oil and protein, and trace amounts of silicone, zeolite or talc are contained in it.

Conclusion

In this application note, each component of mixed foreign materials could be identified and its distribution could be shown by imaging measurement. Identification of the foreign material is expected to help for review of the manufacturing process. Imaging measurement by infrared microscope will be an effective tool to identify foreign material including multiple components, and will apply to the various field such as food and tap water as well as industrial products.