Introduction

To obtain excellent durability for epoxy resins, a specific level of curing is required. Therefore, it is important to identify the optimal curing conditions for quality control, manufacturing management, and product development. Based on ISO 20368, this report describes the dependence of the degree of crosslinking of epoxy resins on the reaction temperature and time determined using a Fourier transform infrared (FT-IR) spectrometer.

Experimental

Refer to ISO 20368 for details about the measurement and analysis methods. The preliminary test specified in ISO 20368 was not performed, and the degree of crosslinking was calculated based on the results of single measurements.

Samples

Two-component mixed epoxy resin (sandwiched between two silicon wafers). This is referred as the measurement sample

Main agent: Epoxy resin

Hardening agent: N,N-Diethyl-1,3-diaminopropane

Measurements

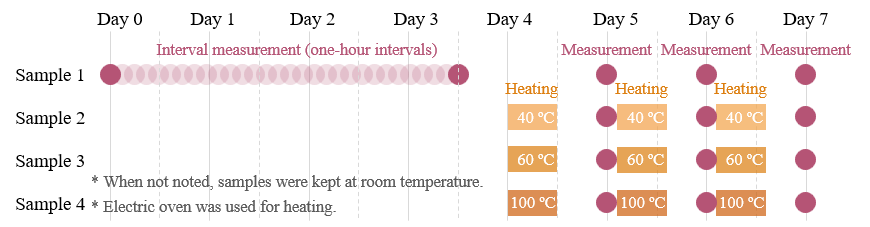

Four samples of the same mixture were prepared (samples 1-4). The spectrum of sample 1 was obtained at one-hour intervals over 3.5 days at room temperature (RT) using the JASCO [Interval Measurement] program, while the other samples were kept in the same room. Since the temperature may affect the degree of crosslinking and the curing time for epoxy resins, on days 4-6, samples 2-4 were held for 12 hours at 40, 60, and 100 ºC, respectively, as shown in Figure 1, and measurements were performed at RT at the end of each day.

Fig. 1 Timetable for measurements, reaction temperatures and reaction times

System

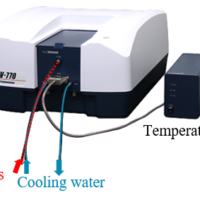

Instrument: FT/IR-4X FT/IR spectrometer

*A sample holder is used to secure the measurement sample

Software: ITM-4X Interval measurement program

Fig. 2 FT/IR-4X FT-IR spectrometer

Parameters

Method: Transmission

Sample volume: Approximately 5 mg

Resolution: 4 cm-1

Accumulations: 16

Temperature: 22 ºC

Humidity: 30%

Keywords

Epoxy resin, adhesive, degree of crosslinking, ISO 20368

Results

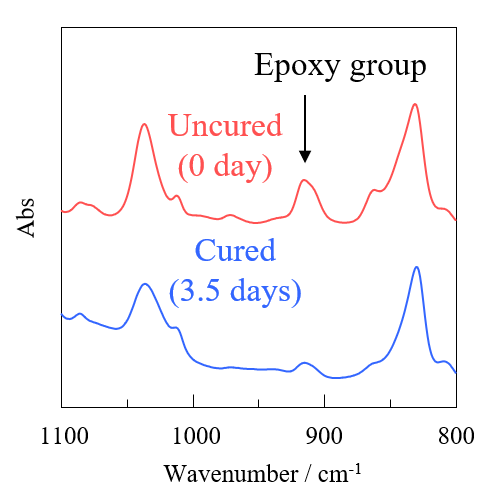

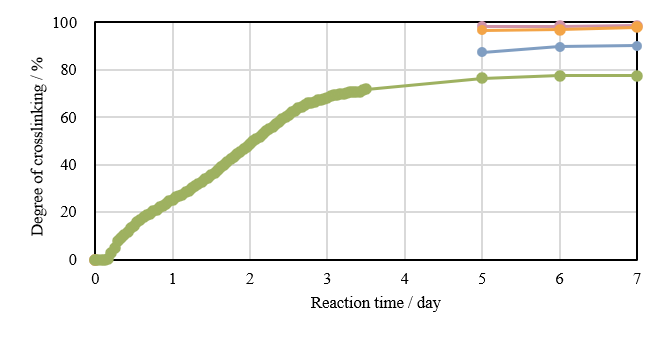

Table 1 and Figure 4 show the results of calculating the degree of crosslinking for each sample in accordance with ISO 20368. When cured at RT, sample 1 reached a steady state in approximately three days. It was also found that the degree of crosslinking increased with temperature, as seen for samples 2-4. For samples 3 and 4, which were heated for 12 hours each day at 60 and 100 ºC, respectively, the degree of crosslinking was close to 100% on the 5th day of curing. For sample 2, which was heated at 40 ºC, the degree of crosslinking gradually increased from 12 to 36 hours of accumulated heating (days 5 to 7), but remained less than those for samples 3 and 4.

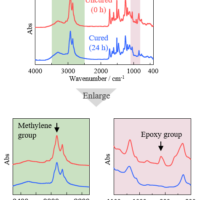

Fig. 3 Spectra of sample 1

Fig. 4 Change in degree of crosslinking

| Sample 1 (RT) | Sample 2 (40 ºC) | Sample 3 (60 ºC) | Sample 4 (100 ºC) | |||||

| Reaction time [day] | Peak height ratio | Degree of crosslinking [%] | Peak height ratio | Degree of crosslinking [%] | Peak height ratio | Degree of crosslinking [%] | Peak height ratio | Degree of crosslinking [%] |

| 0 | 0.375 | 0.362 | 0.406 | 0.460 | ||||

| 1 | 0.281 | 25.1 | – | – | – | |||

| 2 | 0.192 | 48.9 | – | – | – | |||

| 3 | 0.119 | 68.3 | – | – | – | |||

| 3.5 | 0.106 | 71.8 | – | – | – | |||

| 5 (12 hours heating) | 0.088 | 76.5 | 0.046 | 87.2 | 0.013 | 96.8 | 0.009 | 98.1 |

| 6 (24 hours heating) | 0.85 | 77.5 | 0.037 | 89.7 | 0.013 | 96.9 | 0.008 | 98.3 |

| 7 (36 hours heating) | 0.085 | 77.5 | 0.035 | 90.3 | 0.008 | 98.0 | 0.007 | 98.5 |

These results show that the degree of crosslinking of this epoxy resin is strongly affected by temperature, and the higher the reaction temperature, the larger the degree of crosslinking.

Conclusion

The degree of crosslinking of epoxy resins was successfully evaluated for different reaction temperatures and times. The results obtained can be used to improve the quality and manufacturing efficiency for epoxy resins, such as by adding a suitable heating process.

References

Plastics — Epoxy resins — Determination of degree of crosslinking of crosslinked epoxy resins by Fourier Transform Infrared (FTIR) Spectroscopy (ISO 20368)